Understanding Low Viscosity Engine Oil In Heavy-Duty Segment And Its Formulation Challenges

In recent years, the use of low-viscosity engine oils in the heavy-duty segment has been on the rise, driven by the need for better fuel efficiency, lower emissions, and enhanced engine performance. Low viscosity oils, typically found in grades such as 5W-30 or 0W20, offer significant advantages, particularly in reducing internal engine friction during cold starts and under high-load conditions. By minimizing friction, these oils help improve fuel economy and reduce greenhouse gas emissions, which is essential in meeting increasingly stringent environmental regulations, such as Euro VI and EPA 2027 standards.

Emissions from the Transport Sector in India

The transport sector contributes 25% of global carbon dioxide (CO2) emissions from fuel combustion. In India, it ranks as the third highest CO2 emitting sector, with road transport responsible for over 90% of emissions within this category. Heavy-duty vehicles, particularly those over 12 tons, account for approximately 60% of fuel consumption and greenhouse gas (GHG) emissions in the heavy-duty vehicle fleet. Consequently, regulations are in place to lower fuel consumption and emissions from diesel-powered trucks and buses. To comply with Indian CAFÉ regulations, energy-efficient lubricants are the most cost-effective solution, as they typically do not necessitate modifications to vehicle designs.

Energy Losses in the Engine

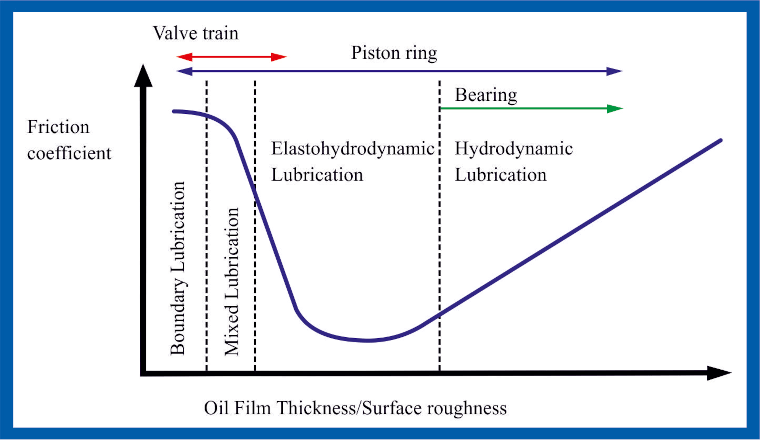

Energy loss in engines primarily occurs due to friction in four key areas: the piston and cylinder, the valvetrain, and the crankshaft. The cam and tappet contacts contribute significantly to friction within the valvetrain, operating under boundary and elastohydrodynamic conditions. In the piston assembly, friction is influenced by mixed, elastohydrodynamic, and hydrodynamic regimes, while the engine bearings predominantly function in hydrodynamic conditions. Lubricating oil is crucial for maintaining the oil film thickness and managing viscous drag, especially in the full hydrodynamic regime. Additionally, the lubrication properties of the oil can affect friction in boundary or mixed lubrication regimes.

Reducing Viscosity of the Lubricants - A Promising Option

Using a low-viscosity lubricant is the most efficient and cost-effective way to lower engine friction out of all the solutions available. By decreasing viscous drag, lower viscosity engine oils lower friction and produce modest but noticeable increases in fuel efficiency.

Therefore, the viscosity grades of the lubricants shifted from 15W40 and above to lower viscosity grades like 10W-40, 10W-30 and 5W-30. Because it lowers the frictional forces, lower viscosity and the inclusion of friction modifiers are common in gasoline engines. On the other hand, excessive viscosity decrease puts engine component durability at risk. Consequently, there may be a limit to viscosity reduction, which is typically higher for diesel engines than for gasoline engines.

Challenges of Low Viscosity Engine Oil

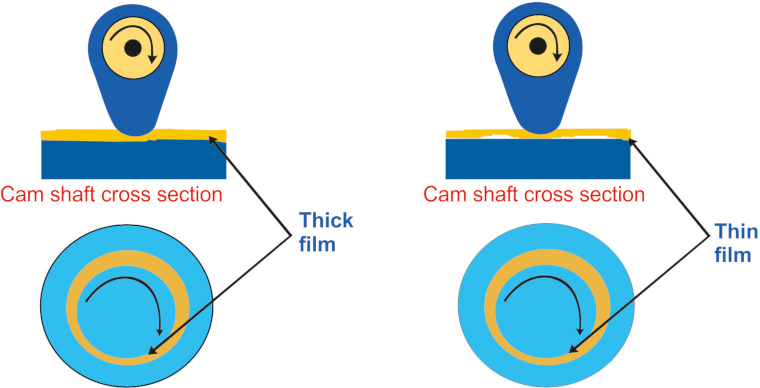

One of the primary challenges in transitioning to lower-viscosity lubricants is achieving a balance between improving fuel economy and ensuring the durability of engine components. Low-viscosity lubricants tend to create thinner oil films, making it more difficult for the oil to maintain adequate separation between loaded contact surfaces within the engine. This can result in increased wear rates. Figure 2 shows Schematic representation of film forming potential of high and viscosity oil in cam shaft and journal bearing cross section.

Therefore, it is essential to develop lubricant formulations with the right combination of base oils and additives that promote fuel efficiency while still protecting the longevity and performance of the engine.

Low Viscosity Grades in Heavy-duty Diesel Engine Oil Specification

The government, original equipment manufacturers (OEMs), and consumers have been the primary forces behind recent modifications to engine oil formulation and specifications. API (American Petroleum Institute) creates oil categories based on various product attributes for American Auto industry. In response to the automotive industry’s push to lower fuel consumption and CO2 emissions, API introduced two new engine oil categories in 2016: CK-4 and FA-4. While API FA-4 concentrates on improving fuel efficiency through reduced viscosities, the API CK-4 specification preserves backward compatibility.

Formulation Challenges Stringent High Temperature High Shear Viscosity (HTHS)in Low Viscosity Engine Oil

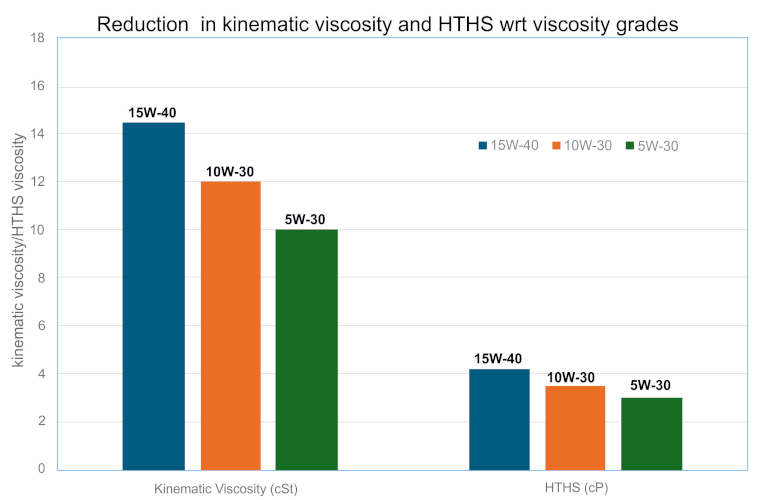

High-temperature high-shear viscosity (HTHS) assesses the viscosity, or flow resistance, of engine lubricants at elevated temperatures while maintaining constant shear conditions. This illustrates the tight tolerances and high-speed interactions that occur between hot engine parts. Greater potential for increased fuel efficiency is indicated by a lower HTHS viscosity. Along with the more popular 15W-40, API CK-4 does permit low-viscosity engine oils like 10W-30 and 5W-30.

To attain a minimum HTHS of 3.5 cSt, API CK4 SAE 10W-30 oil must be formulated toward the higher end of the SAE viscosity limits. As a result, most API CK-4 10W-30 engine oils typically have viscosities above 11.5 cSt, which is significantly higher than the minimum requirement of 9.3 cSt.

API FA-4 engine oils are designed with a lower HTHS viscosity than their API CK-4 counterparts. This implies that these oils move through the engine more quickly at working temperatures, giving the internal hardware the essential lubrication it needs. The ease of flow also reduces friction, fuel consumption, and lowers exhaust emissions to improve the overall efficiency of the vehicle.

In contrast, API FA-4 oils typically have HTHS values between 2.9 and 3.2 cSt and viscosities of about 10 cSt at 100°C. To satisfy both viscosity and HTHS requirements, careful selection of base oil combinations and viscosity modifiers (VM) is crucial. Even oils formulated to meet FA-4 specifications need to incorporate high-quality low-viscosity base oils. Figure 4 shows viscosity and HTHS difference of CK-4 15W-40, CK-4 10W-30 and FA-4 5W-30 viscosity grades.

Stringent Volatility Limit

Evaporation loss plays a critical role in engine lubrication, particularly at high temperatures. When oil is subjected to these elevated temperatures, some of its components can evaporate, leading to increased oil consumption and potential changes in oil characteristics. To address this issue, engine manufacturers and API specifications set limits on the maximum evaporation loss permitted.

In low-viscosity engine oil, volatility is important because it directly impacts oil consumption, drain intervals, and overall engine performance. Lower volatility is crucial for maintaining oil’s lubricating properties, preventing excessive oil burning, and maximizing fuel efficiency. Evaporation loss plays a critical role in engine lubrication, particularly at high temperatures. Some of the components in oil may evaporate when exposed to extremely high temperatures, which could result in changes to the oil’s properties and greater consumption.To address this issue, engine manufacturers and API specifications set limits on the maximum evaporation loss permitted. Low viscosity oils must have lower volatility to ensure they retain their lubricating properties, reduce the likelihood of oil burning, and enhance fuel efficiency. Consequently, base stocks with lower viscosity, greater viscosity index (VI), and lower volatility are needed for low-viscosity engine oil formulations. The price and accessibility of premium base stocks have a significant impact on ultra-low viscosity lubricants. Therefore, choosing base stocks carefully is crucial.According to API guidelines, the Noack volatility limit is higher in the CK4 and FA4 categories (13%), as opposed to the 15% limit in the earlier categories. SAE 15W-40 is the prevalent grade require Gp II base oil whereas FA4 is the fuel economy category where 10W-30 and 5W-30 is the prevalent low viscosity grades and to meet the volatility requirement Gp III base oils are required.

Shear Stability The ability of an oil to resist mechanical breakdown under extreme stress is known as shear stability. When the polymers in multigrade oils are sheared into smaller fragments, it can lead to a decrease in viscosity, potentially compromising the oil’s ability to protect essential engine components. When assessing shear stability, the effectiveness of viscosity modifiers (VMs) is essential. These modifiers are susceptible to permanent shearing, especially when they pass through engine gears or oil pumps. To guarantee long-lasting performance, it is crucial to select the appropriate kind of VMs that complies with the shear stability requirements established by OEM and industry standards.

Shear stability is vital for low-viscosity oils, which are formulated to enhance fuel efficiency. These oils maintain a thinner film thickness to safeguard moving engine parts. The protective film’s strength is reduced if shearing causes the viscosity to drop, which could lead to increased wear on engine parts. Consequently, a new test for high-temperature high-shear (HTHS) viscosity after shearing has been introduced for the first time in the latest heavy-duty engine oil specifications, API CK4 and FA4.

Viscosity Trend in Indian Market

SAE 15W-40 is the most often used grade in the heavy-duty diesel industry globally. However, this grade is at its highest point and is predicted to fall by 2030. Moreover, the on-highway industry is anticipated to rapidly transition to SAE 10W-30. Additionally, FA-4 10W-30/ SAE 5W-30 will continue to be slow until entire fleets turn over, such that OEMs specifically endorse API FA-4 fluids.

A decade ago in India, the SAE 10W-30 grade was practically non-existent in the heavy-duty segment. However, with the introduction of BS VI emission standards, the adoption of CK4 10W-30 grade has significantly increased. This grade is now commonly used by original equipment manufacturers (OEMs) for both plant filling and service filling, following extensive testing on BS VI vehicles. In contrast, the adoption of the lower viscosity oil, FA4 5W-30, has seen slower progress, which may be attributed to its compatibility with existing hardware.