Use Zone Inspections for Early Problem Detection

Early detection means frequent detection. While daily one-minute visual inspections have been discussed previously in Machinery Lubrication magazine, many questions remain, including where and how you inspect, what the observed conditions mean, and how you penetrate a machine’s exoskeleton exterior without X-ray vision.

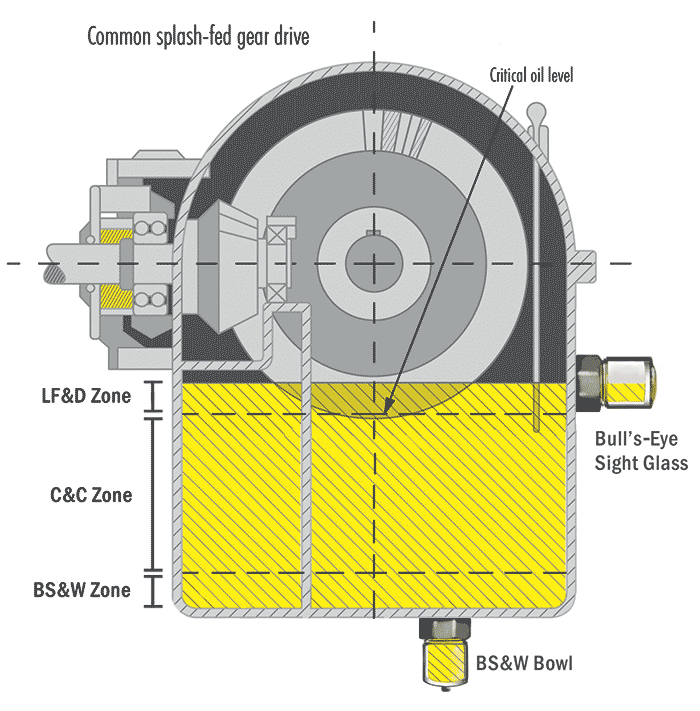

There are three important inspection zones in common oil reservoirs and sumps. These zones have a story to tell about your oil and machine. They might be difficult to reach, but difficult does not mean impossible and certainly doesn’t mean unnecessary. Let’s get inside that exoskeleton and see what we need to know.

Level, Foam and Deposits (LF&D) Zone

Machines don’t just need some lubricant or any lubricant. Rather, they need a sustained and adequate supply of the right lubricant. Adequate doesn’t just mean dampness or the nearby presence of lubricant. What’s defined as adequate varies somewhat from machine to machine but is critical nonetheless. High-speed equipment running at full hydrodynamic film has the greatest lubricant appetite and is also the most punished when starved. Machines running at low speeds and loads are more forgiving when lube supply is restricted. Even these machines can fail suddenly when severe starvation occurs.

There are four keys to solving starvation problems using proactive maintenance:

There are four keys to solving starvation problems using proactive maintenance:

- Identify the required lube supply or level to optimize reliability.

- Establish and deploy a means to sustain the optimized supply or level.

- Establish a monitoring program to verify that the optimized supply or level is consistently achieved.

- Rapidly remedy non-compliant lube supply or level problems.

For non-circulating wet-sump machines, slight changes in oil level can be catastrophic. These include bath, splash, oil-ring, flinger/slinger and similar lubricant supply methods originating from an oil sump. For these machines, frequent confirmation that the correct oil level is maintained has everything to do with machine reliability. This is best done by properly mounted and frequently inspected level gauges.

Some things float, and other things sink. What floats is lighter than oil. It rises by buoyancy. For instance, certain low-density additives can rise and form a visible film on the oil’s surface. Air bubbles, water vapor, natural gas and refrigerants are all buoyant. Once they get to the oil’s surface, they either release gases into the atmosphere or create bubbles. A stable layer of bubbles forms foam. Foam is disruptive for a variety of reasons, but most importantly it is associated with lubricant starvation. For more information on the causes and remedies of aeration and foam, see www.machinerylubrication.com/Read/690/aerated-oil.

Aeration and foam can be detected as long as you have a window. Sight glasses and level gauges mounted in ports that are centerline to the oil level enable this and should be included in a daily inspection program. This allows both oil level and aeration issues to be checked simultaneously. Optionally, hatches and access ports can also facilitate early detection of abnormal foam and aeration conditions.

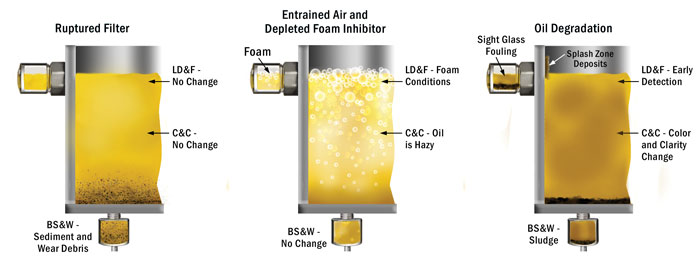

Oil level sight glasses and internal tank inspections permit detection of surface deposits as well (e.g., varnish and sludge). The worst of this usually builds just above the oil level, called the splash zone, and looks similar to a tar-like bathtub ring. The cooler metal surfaces above the oil level enable splashed oil to deposit insoluble suspensions (condensation) that accumulate over time. These adherent gums and resins are associated with a range of problems that require early detection including oil oxidation, microdieseling and electrostatic discharge. An advanced case of this is shown in Figure 1. In a similar way, sight glasses can also be used for early detection of deposits. The acrylic or glass used often becomes fouled by deposits when high varnish potential conditions exist.

Bottom Sediment and Water (BS&W) Zone

Sooner or later gravity has a way of dragging things out of oil. On one hand, this is beneficial, as sedimentation and stratification of impurities can have a moderate cleansing effect on the oil. On the other hand, there are also many hazards and risks, which will be discussed later.

Sooner or later gravity has a way of dragging things out of oil. On one hand, this is beneficial, as sedimentation and stratification of impurities can have a moderate cleansing effect on the oil. On the other hand, there are also many hazards and risks, which will be discussed later.

Most of the things you don’t want in your oil are heavier than the oil. These include hard solids (dirt, wear debris, corrosion debris, process solids, etc.), soft solids (sludge, agglomerated oxides, microbial contaminants, dead additives, etc.) and stratified liquids (e.g., free water and glycol).

Low-lying impurities can be referred to as bottom sediment and water (BS&W). BS&W includes all of the following:

- Agglomerated sludge (accumulations of resinous solids, gums, oxides and dead additives)

- Stratified solids (dense zones of soft contaminants, oxides and dead additives)

- Sediment (settled hard contaminants like dirt and wear debris)

- Water and other settled liquid contaminants (e.g., antifreeze)

Often the sludge and sediment found on the bottom of sumps and reservoirs are tightly bound by water. Most oil impurities are polar (water loving) in nature. When free and emulsified water contaminates an oil, this water can act as a mob to collect and bind together these impurities. Eventually, the growing sludgy mass is pulled by gravity to the sump floor. Dirt and wear debris that fell by normal sedimentation can also cling to these sludge pools.

How to Prevent the Fishbowl Effect

In an ideal world, you wouldn’t allow bottom sediment and water (BS&W) to accumulate, and oil changes wouldn’t be necessary. However, nobody lives in an ideal world. While you can’t eradicate BS&W in the real world, you can control its accumulation and resuspension by employing the following suggestions:

- Use a BS&W bowl to monitor and periodically time the purge of BS&W “on condition.” This will prevent hazardous accumulations and help track the source and rate of generation.

- After a needed oil drain, use a discharge wand from a filter cart to rinse out remaining BS&W from tank and sump bottoms before refilling with new fluid. Confirm that the rinse was successful by inspection.

- After new oil has been added, circulate the fluid through a filter at the highest flow rate possible before the machine is started and put under load. Use a filter cart, if necessary. Allow the total oil volume to turn over no less than five times. Do a simple patch test or particle count to confirm cleanliness, especially for critical equipment.

Early Detection of BS&W is Key

As mentioned previously, BS&W is symptomatic of a host of problems and issues related to your oil and machine. Failed and degraded oil, environmental contaminants (e.g., dirt and water), active machine wear and corrosion all produce BS&W. It is important to know if BS&W is present so you can start the troubleshooting process and find the originating cause. This can be accomplished by 1) using BS&W bowls, 2) periodically taking drain port samples or 3) using a drop-tube vacuum sampler in which the tube is lowered to the bottom of the sump.

The seriousness of BS&W goes far beyond machine problems that produce sediment and water. BS&W can lead directly to sudden-death machine failure. For instance, disturbing the sediment in oil lubrication systems can produce what is called the “fishbowl effect.” Those who have had tropical fish know that the slightest agitation of an unchanged fish bowl causes the water to become murky with sediment, uneaten food and excrement. In the same sense that you wouldn’t want a loaded oil filter to burst, sending a dense debris field downstream, you also wouldn’t want to agitate the BS&W in your sumps and reservoirs. Imagine this sequence of events relating to an oil change:

- The drain port of a reservoir is removed, and the aged oil flows out by gravity into a waste oil container.

- Some of the BS&W is purged with the oil, but much of it stays clinging to the reservoir floor.

- During the drain, oil flowed by gravity toward the tank through piping, valves, pumps and filter housings, carrying suspended particles that were previously trapped in nooks and crannies. Some of these backwashed particles resettle in various locations, presenting the risk that they will be re-entrained into the oil when the machine is restarted.

- When fresh new oil comes plunging into the reservoir, the BS&W is stirred up into a murky mass.

- When the machine is restarted, the suspended reservoir muck and the displaced particles in the lines and machine components become mobilized by the flowing fluid and travel throughout the system.

- Some of these suspended particles induce accelerated wear in frictional load zones (bearings, gears, pumps, etc.), while others get trapped in narrow glands, oilways and orifices, causing restricted oil flow (starvation conditions).

- The dense concentration of particles and impaired oil flow start a chain of events that ends in machine failure. This happens more often than you might think.

Color and Clarity (C&C) Zone

Transitions in oil color and clarity (C&C) are common precursors to bottom sediment, sludge, varnish, emulsified water, entrained air and stable foam conditions. For this reason, it’s important to know when color and clarity changes are occurring. The oil is trying to tell you where it hurts.

Tracking C&C can be done by simple and routine visual inspections, such as:

- Color Transitions - These are transitions from oil chemistry changes and color-producing contaminants. The observed oil color is typically compared to new oil and/or the previous oil that was sampled. Color bodies (chromophoric compounds) alert inspectors to degrading additives, base oil degradation and a host of contaminants possessing unique color markers.

- Clarity Transitions - Clarity changes are generally due to the presence of suspended insolubles, entrained air and emulsions. These can range from a slight haze in the oil to cloudy/murky conditions. Advanced conditions result in the oil becoming completely opaque (pitch black). Good lighting is required during inspection, including the optional use of a strong laser light source.

C&C conditions relate to the active body of the oil and are less influenced by gravity and stratification. Still, C&C transitions can be seen when inspecting low-lying oil (tank drains and BS&W bowls) but also elsewhere, such as with an oil level gauge or inline sight glass. You can even examine the oil’s color and clarity in a bottle during routine sampling.

Color and clarity correlate to the transmission and spectral absorption of light by oil. Examples of conditions and contaminants that produce color and clarity transitions are shown in the table below.

Teaming Zone Inspections to Learn What’s Not Happening

| Offending Condition | Colour | Clarity |

|---|---|---|

| Wrong oil or cross-contamination (mixed oils) | S | S |

| Emulsified water | R | A |

| Dissolved water | R | R |

| Glycol contamination (coolant) | S | S |

| Insoluble additives | S | A |

| Degraded additives | S | S |

| Base oil oxidation | A | A |

| Thermal degradation of the base oil | A | A |

| Chemical contamination | S | S |

| Hydrolysis | S | S |

| High oil varnish potential (microdieseling, electrostatic discharge, etc.) | S | S |

| Entrained air | S | A |

| Waxy suspensions (cold temperature related) | R | A |

| Microbial contaminants | R | S |

| Typical levels of dirt or wear debris | R | R |

| A=Always, S=Sometimes, R=Rarely | ||

While condition monitoring is about knowing what is happening to your oil and machine, it is also about what is not happening. For example, say you visually inspect your oil and machine in all three zones (LF&D, BS&W and C&C), and observe excellent, healthy conditions. What can you conclude? Well, you can determine that there are approximately 25 things that could be going wrong (in the oil and machine) that aren’t going wrong just because you have passing marks from these zone inspections. Among the multitude of things not occurring are the following:

- Base oil oxidation

- Thermal degradation

- Additive stratification (dropout)

- Microbial contamination

- Free or emulsified water contamination

- Air induction conditions

- Impaired air-release conditions

- Stable foam conditions

- Antifreeze contamination

- Sludge conditions

- Varnish potential conditions

- Varnish laydown conditions

- Heavy sediment from a failed filter

- Heavy sediment from contaminant ingression

- Advanced machine wear conditions (certain cases)

- Depletion of several important additives

Oil that is exhibiting issues like those in the list above will require urgent attention to troubleshoot and remediate the offending problem. If the cause of the condition(s) is unclear, laboratory analysis of the oil and/or BS&W may be needed.

It is worth emphasizing that these zone inspections are not a substitute for routine oil analysis. Also, samples that are routinely analyzed by laboratories should not be taken from the bottom of sumps and reservoirs. Instead, they should be extracted from live, turbulent fluid zones using the proper methods and tools.

For those who strive for lubrication-enabled reliability (LER), the opportunity comes from paying close attention to the “Big Four.” These are critical attributes of the optimum reference state (ORS) discussed frequently in this column and needed to achieve lubrication excellence. The “Big Four” individually and collectively influence the state of lubrication and are largely controllable by machinery maintainers. They are well-known but frequently not well-achieved. They are:

- Correct lubricant selection

- Stabilized lubricant health

- Contamination control

- Adequate and sustained lubricant level/supply

It is comforting to know that the last three of the “Big Four” can be largely examined and confirmed by employing a rigorous zone inspection program. Yes, early detection means frequent detection. It’s within your control. Opportunity knocks!